.png)

You do not know the reason why calibrating measuring instruments is so important? Let us see the explanation below!

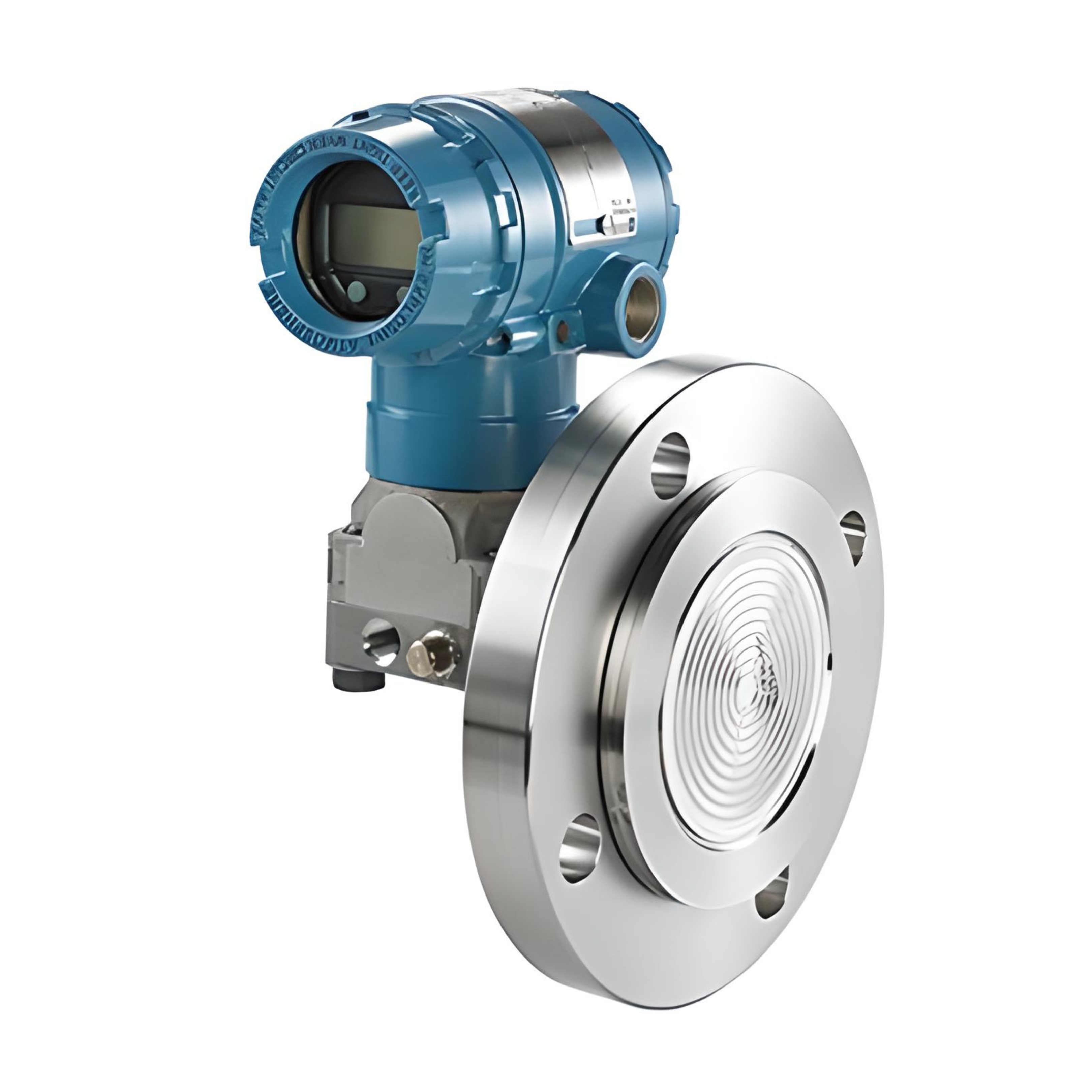

Calibration is a verification process that the accuracy of a measuring instrument is in accordance with its design. Calibration is usually done by comparing a standard that is connected to national and international standards and certified reference materials.

Calibration Purpose

There are several goals that you will get by performing calibration, including:

1. To determine the deviation of the truth that exists in a conventional value. This value is obtained from a predetermined measuring instrument.

2. To guarantee the measurement results, so that they comply with applicable standards. If done on an object, it is expected that the object can be calculated thoroughly without any errors.

3. To ensure accuracy, so as to support efforts to improve the quality of services or objects in the future.

4. To support the quality system applied to an object or activity and measure whether a tool is still suitable for use or not.

5. To achieve usable conditions, so that objects can be used optimally.

By calibrating, it can be seen to what extent the differences are occurring using a predetermined measuring instrument.

1. Guarantees traceability of the resulting size value.

By calibrating measuring instruments in an accredited laboratory, measurement results can be accepted anywhere, because all calibration laboratories will refer to the same source, namely the International Standard Unit.

2. Avoiding product defects.

If the measuring instrument is not calibrated or the calibration period has passed, but is still used to measure a product. What if there is a big deviation? Of course, it would be very detrimental, wouldn't it? You can get rid of this worry by performing regular calibrations at an accredited calibration laboratory!

3. Maintain the condition of the measuring instrument to keep it according to its specifications.

Measurement tools can experience a decrease in performance after being used for a certain period of time. By calibrating regularly, you can find out whether the measuring instrument is still within specifications or needs repair or even needs to be replaced.

4. Avoid the risk of danger and minimize work accidents.

How are the lighting conditions in your factory? What is the noise level in your workplace? Of course, light intensity and noise level need to be measured, right? Well, you also have to calibrate measuring tools related to safety on a regular basis, for work safety.

So, that is the reason why calibration is so important! For further discussion, please contact us!